Introduction

Welcome to our comprehensive guide on the conductivity of duct tape! If you've ever wondered about the electrical properties of this versatile adhesive, you're in the right place. In this article, we'll explore the surprising truth about whether duct tape can conduct electricity, dispel common myths surrounding its conductivity, and delve into practical applications for this unique property.

The Conductivity of Duct Tape

Many people are surprised to learn that duct tape does indeed have some level of electrical conductivity. While it may not be as conductive as traditional metal wiring, it can still carry a current under certain conditions. Understanding how and why duct tape conducts electricity is essential for using it safely and effectively in various applications.

Common Misconceptions

One of the most prevalent misconceptions about duct tape is that it is entirely non-conductive. This belief has led to many DIY enthusiasts unknowingly using duct tape in situations where electrical insulation is crucial. By debunking these myths and understanding the true nature of duct tape's conductivity, you can avoid potential safety hazards and make informed decisions when working with this material.

Practical Applications

The ability of duct tape to conduct electricity opens up a range of practical applications beyond its traditional use as a quick fix for household repairs. From DIY electrical projects to industrial applications, understanding its conductivity can help you harness its potential in innovative ways while ensuring safety and reliability.

The Science Behind Conductivity

When it comes to understanding the conductivity of duct tape, it's important to first grasp the concept of electrical conductivity. Electrical conductivity refers to a material's ability to conduct an electric current. In simpler terms, it's the measure of how well a substance allows electricity to flow through it. This property is crucial in determining whether a material can be used for electrical purposes or not.

Factors affecting conductivity are numerous and varied. For duct tape, factors like the type of adhesive used, the composition of the backing material, and even the presence of conductive additives can impact its overall conductivity. Additionally, factors such as temperature, pressure, and humidity can also influence how well duct tape conducts electricity.

Testing duct tape's conductivity is an essential step in understanding its electrical properties. There are various methods for testing this, including using a multimeter to measure resistance or employing specific testing equipment designed for assessing electrical conductivity in materials like duct tape.

Now that we've laid the groundwork for understanding conductivity and its relevance to duct tape, let's delve into mythbusting: does duct tape really conduct electricity?

Mythbusting: Does Duct Tape Really Conduct Electricity?

Many people believe that duct tape cannot conduct electricity due to its insulating properties, but the reality may surprise you. While it is true that most traditional duct tapes are designed to be non-conductive, there are specific types of duct tape that are manufactured with conductive properties. This means that certain brands of duct tape can indeed conduct electricity when used in the appropriate manner.

Popular Beliefs vs. Reality

The popular belief that duct tape cannot conduct electricity stems from its common use as a quick fix for electrical insulation and repairs. However, this misconception overlooks the fact that not all duct tapes are created equal. Some specialized types of duct tape are engineered with conductive materials, allowing them to effectively carry an electrical current. It's important to differentiate between regular and conductive duct tapes to avoid potentially dangerous situations when working with electricity.

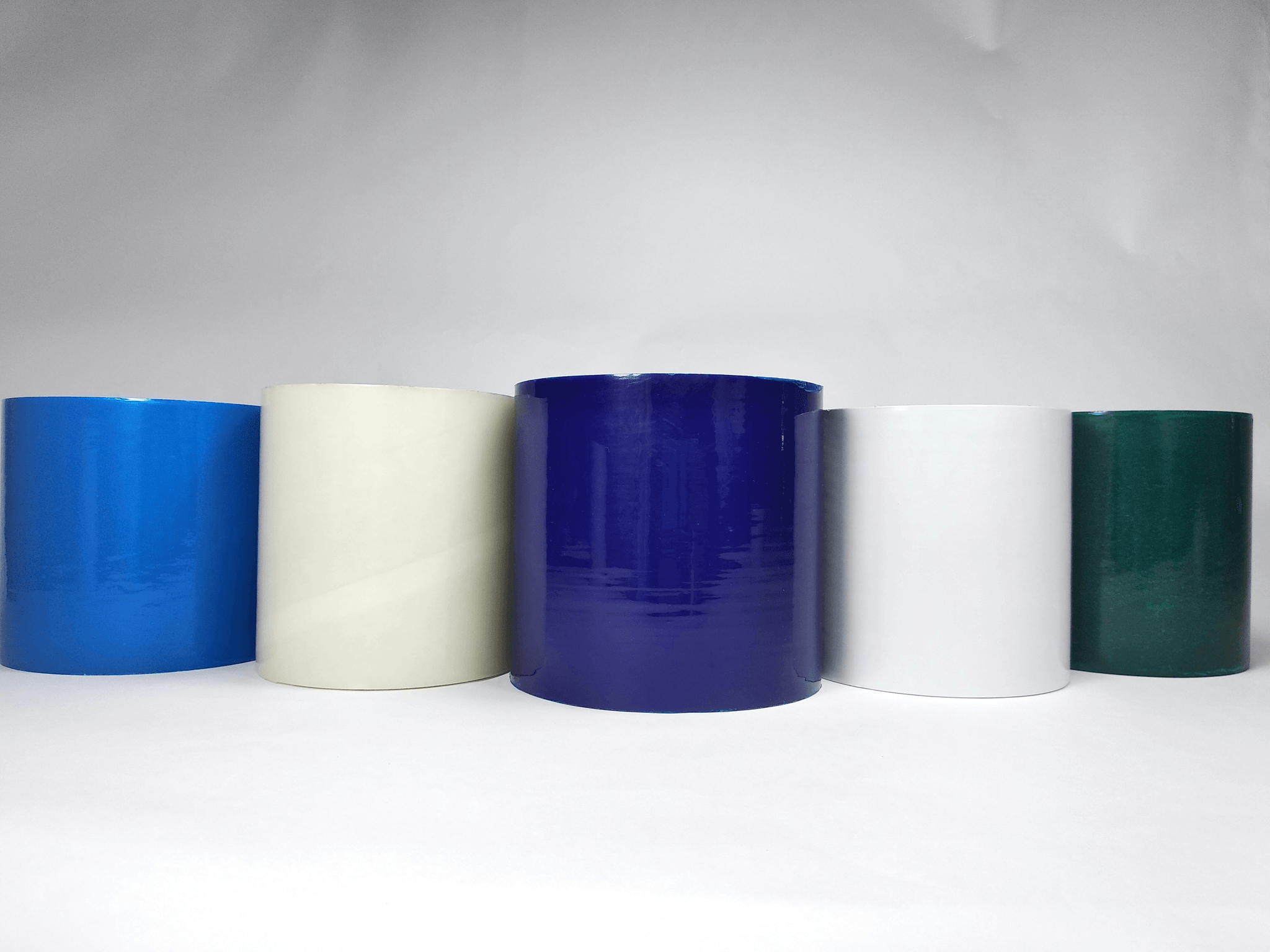

Conductivity in Various Duct Tape Brands

When it comes to testing the conductivity of various duct tape brands, it's crucial to consider the specific composition and intended use of each product. While standard cloth-backed duct tapes typically do not conduct electricity, there are metallic or metal-coated variants designed for electrical applications that have been engineered to be electrically conductive. These specialized types of duct tape can be invaluable for tasks ranging from grounding and shielding to DIY electrical repairs.

Safety Precautions

When working with any type of electrical material, safety should always be a top priority. If you plan on using conductive duct tape for electrical purposes, take the necessary precautions by ensuring proper insulation and grounding techniques are employed in your project. It's also essential to carefully follow manufacturer guidelines and recommendations for safe handling and usage of conductive materials to minimize any potential risks associated with working around electricity.

Practical Uses of Conductive Duct Tape

Duct tape's conductivity makes it a versatile tool for DIY electrical repairs. Whether you're fixing frayed wires or securing loose connections, conductive duct tape can provide a quick and effective solution. With its adhesive backing and ability to carry electrical current, it's a handy addition to any homeowner's toolbox.

DIY Electrical Repairs

When dealing with minor electrical issues around the house, conductive duct tape can be a lifesaver. From repairing damaged cords to securing loose connections, this versatile tape provides a temporary fix until you can address the problem more permanently. Just remember that it's not a long-term solution for major electrical repairs, so always consult a professional for safety.

EMI/RFI Shielding

Electromagnetic interference (EMI) and radio-frequency interference (RFI) can disrupt electronic devices and sensitive equipment. Conductive duct tape is an effective solution for shielding against these interferences, providing protection from external signals that could affect the performance of your electronics.

Industrial Applications

In industrial settings, conductive duct tape plays a crucial role in electrical maintenance and repair work. Its ability to carry electrical current makes it an essential tool for quick fixes on machinery and equipment. From securing wiring to providing temporary insulation, this type of duct tape is a valuable asset in industrial maintenance.

As seen here, conductive duct tape is being used to secure wiring in an industrial setting where traditional tools may not be as effective or readily available.

Stay tuned for the next section on safely working with conductive duct tape!

How to Safely Work with Conductive Duct Tape

When working with conductive duct tape, it's important to handle and store it properly to maintain its effectiveness. Store the tape in a cool, dry place away from direct sunlight and extreme temperatures. Avoid exposing it to moisture or humidity, as this can compromise its conductivity over time. When handling the tape, be sure to wear gloves to prevent any oils or residue from your hands affecting its performance.

Proper Handling and Storage

To ensure the longevity of your conductive duct tape, always handle it with clean hands and avoid touching the adhesive side unnecessarily. When storing the tape, keep it in its original packaging or wrap it in plastic to protect it from dust and debris. Additionally, make sure to seal the package tightly after each use to prevent any exposure to air or moisture that could impact its conductivity.

Avoiding Electrical Hazards

When using conductive duct tape for electrical repairs or installations, always remember to turn off the power source before applying the tape. This will prevent any potential electrical hazards and ensure your safety while working with live wires or circuits. It's also essential to inspect the area for any signs of damage or wear before applying the tape to avoid exacerbating existing electrical issues.

Tips for Effective Insulation

For effective insulation using conductive duct tape, ensure that the surface is clean and dry before application. Smooth out any wrinkles or air bubbles when applying the tape to maximize its contact with the surface for optimal conductivity. Additionally, consider using multiple layers of tape for added insulation and protection against electrical currents.

Understanding the Limitations of Duct Tape

Duct tape is a versatile tool, but it does have its limitations. One of the most significant limitations is its temperature and moisture resistance. When exposed to extreme temperatures or high levels of moisture, duct tape can lose its adhesive properties and become less effective as an electrical insulator. This can lead to potential safety hazards and compromised electrical connections.

Temperature and Moisture Resistance

In hot environments, the adhesive on duct tape can soften and lose its grip, leading to peeling or detachment from surfaces. Similarly, in cold temperatures, the adhesive can become rigid and brittle, causing it to crack or break apart easily. Additionally, exposure to moisture can cause the tape to become less sticky over time, reducing its ability to maintain a secure bond.

Long-Term Reliability

While duct tape may provide a quick fix for electrical insulation needs in the short term, it may not be reliable for long-term use. Over time, the adhesive properties of duct tape can degrade, leading to weakened bonds and compromised insulation. This can result in electrical issues such as short circuits or exposed wiring, posing potential safety risks.

Alternative Electrical Insulation Materials

To overcome the limitations of duct tape in electrical applications, it's important to consider alternative insulation materials that offer greater reliability and durability. Options such as heat-shrink tubing, silicone sealants, or specialized electrical tapes specifically designed for high-temperature or moisture-prone environments can provide more robust insulation solutions.

By understanding these limitations of duct tape when it comes to temperature and moisture resistance as well as long-term reliability in electrical applications, homeowners and DIY enthusiasts can make informed decisions about choosing the right materials for their projects while ensuring safety and effectiveness.

Conclusion

Understanding the conductivity of duct tape can have numerous benefits for DIY enthusiasts and professionals alike. By knowing how duct tape conducts electricity, individuals can make informed decisions about its use in various applications, ensuring safety and efficiency.

Benefits of Knowing Duct Tape Conductivity

Knowing whether or not duct tape conducts electricity can prevent potential hazards during DIY electrical repairs or projects. By understanding its conductivity, individuals can avoid using duct tape in situations where it may pose a risk of electrical shock or fire.

Taking Advantage of Conductive Properties

For those who are aware of the conductive properties of duct tape, there are opportunities to utilize it in EMI/RFI shielding applications or other scenarios where electrical conductivity is desired. This knowledge allows for creative problem-solving and innovative uses for duct tape.

Safely Harnessing Electrical Potential

By being informed about the conductive nature of duct tape, individuals can safely harness its electrical potential when used appropriately. This includes taking necessary precautions and following best practices to ensure that the conductive properties of duct tape are utilized effectively and safely.

In conclusion, understanding the conductivity of duct tape empowers individuals to make informed decisions about its use in various applications, enabling them to take advantage of its conductive properties while prioritizing safety and effectiveness. Whether it's for DIY projects or industrial applications, knowing how duct tape conducts electricity is essential for making the most out of this versatile tool.