Introduction

When it comes to the conductivity of stainless steel, many people wonder, Does stainless steel conduct electricity? This question is important for anyone considering using stainless steel in electrical applications. Understanding electrical conductivity and the factors that affect metal conductivity can help shed light on this topic. In this guide, we'll explore the basics of electrical conductivity, delve into the specifics of stainless steel conductivity, and discuss practical applications and considerations for using stainless steel in electrical scenarios.

The Conductivity of Stainless Steel

Stainless steel is a popular metal known for its resistance to corrosion and staining, but its electrical conductivity is often overlooked. The conductivity of stainless steel refers to its ability to conduct electricity, which can be influenced by various factors such as alloy composition, surface finish, and temperature. While stainless steel is not as conductive as other metals like copper or aluminum, it still has practical applications in electrical conductivity due to its durability and resistance to corrosion. Understanding the conductivity of stainless steel is crucial for determining its suitability for specific electrical applications and ensuring optimal performance.

Understanding Electrical Conductivity

Electrical conductivity refers to the ability of a material to conduct an electric current. In simple terms, it is the measure of how easily electrons can flow through a substance. Metals are generally good conductors of electricity because they have free electrons that can move easily from atom to atom. This is why metals like copper and aluminum are commonly used in electrical wiring and components. Understanding electrical conductivity is important in determining the suitability of materials for specific applications, especially in industries where electrical conductivity is a critical factor.

Factors Affecting Metal Conductivity

The electrical conductivity of metals is influenced by several factors, including the number of free electrons available for conduction, the mobility of these electrons within the metal lattice, and the collisions between electrons and atoms. The presence of impurities or alloying elements can also impact conductivity by affecting electron mobility or introducing scattering mechanisms. Additionally, the crystalline structure and grain boundaries within a metal can influence its conductivity. Understanding these factors is crucial for predicting and optimizing the electrical properties of metals for specific applications.

The Basics of Electrical Conductivity

Electrical conductivity is the ability of a material to conduct an electric current. It is a crucial property in various applications, from electronics to construction. Understanding electrical conductivity helps in selecting the right materials for specific uses.

What Is Electrical Conductivity?

Electrical conductivity refers to how well a material allows the flow of an electric current. It is measured in siemens per meter (S/m) and is the reciprocal of electrical resistivity. Materials with high electrical conductivity allow electricity to flow easily, while those with low conductivity impede the flow.

The Role of Electrons in Conductivity

In metals, electrical conductivity is primarily due to the movement of free electrons within the material. When a voltage is applied across a metal, these free electrons move in response, creating an electric current. The number of free electrons and their mobility determine a metal's conductivity.

Conductivity Measurement Units

The unit used to measure electrical conductivity is siemens per meter (S/m). This unit represents how well a material conducts electricity within one meter length. For practical purposes, microsiemens per centimeter (µS/cm) or millisiemens per centimeter (mS/cm) are often used for solutions and other conductive liquids.

Now that we've covered the basics of electrical conductivity, let's delve into whether stainless steel can conduct electricity effectively.

Does Stainless Steel Conduct Electricity?

Stainless steel is a popular metal known for its corrosion resistance and durability, but does stainless steel conduct electricity? The answer is yes, stainless steel does conduct electricity to some extent. The conductivity of stainless steel alloys depends on various factors such as the composition of the alloy, surface finish, and temperature.

Conductivity of Stainless Steel Alloys

Stainless steel alloys are composed of iron, carbon, and at least 10.5% chromium. The addition of other elements such as nickel and molybdenum can also affect the electrical conductivity of the alloy. Generally, stainless steel has lower electrical conductivity compared to other metals like copper and aluminum due to its higher resistance.

Comparing Stainless Steel to Other Metals

When comparing stainless steel to other metals in terms of electrical conductivity, it falls behind highly conductive metals like copper and aluminum. However, stainless steel still has its own unique properties that make it suitable for specific electrical applications where corrosion resistance is essential.

Practical Applications of Stainless Steel Conductivity

Despite its lower electrical conductivity, stainless steel finds extensive use in various electrical applications such as in wiring, connectors, and electronic components where corrosion resistance is crucial. Its ability to withstand harsh environments while maintaining structural integrity makes it an ideal choice for outdoor or marine electrical installations.

As we delve deeper into the world of stainless steel conductivity, it becomes evident that this versatile metal possesses unique properties that make it suitable for specific electrical applications despite not being as highly conductive as other metals like copper or aluminum.

Factors Affecting Stainless Steel Conductivity

Alloy Composition and Conductivity

The alloy composition of stainless steel plays a significant role in determining its electrical conductivity. Different alloys have varying levels of electrical conductivity, with some being more conductive than others. For example, austenitic stainless steel alloys, which contain high levels of nickel and chromium, tend to have lower electrical conductivity compared to other stainless steel grades. On the other hand, martensitic stainless steel, which contains higher levels of carbon, has higher electrical conductivity due to its lower nickel content.

Surface Finish and Conductivity

The surface finish of stainless steel also affects its electrical conductivity. A smooth surface finish allows for better electron flow and thus higher conductivity, while a rough or pitted surface can impede the flow of electrons and reduce the material's overall conductivity. This is why it's important to consider the finishing process when using stainless steel in applications where electrical conductivity is crucial.

Temperature and Conductivity

Temperature has a significant impact on the electrical conductivity of stainless steel. In general, as temperature increases, the resistance to electron flow also increases, leading to decreased electrical conductivity. This phenomenon is known as thermal resistivity and is an important consideration when designing systems that involve the use of stainless steel in high-temperature environments.

Now that we've explored how alloy composition, surface finish, and temperature can affect the electrical conductivity of stainless steel let's move on to discussing how these factors can be tested in practical applications.

Testing Stainless Steel Conductivity

When it comes to testing stainless steel conductivity, there are a few different methods that can be used to determine its electrical properties. One common method is through laboratory tests, which involve subjecting the stainless steel to controlled conditions and measuring its conductivity. These tests are often conducted using specialized equipment that can accurately measure the electrical properties of the metal.

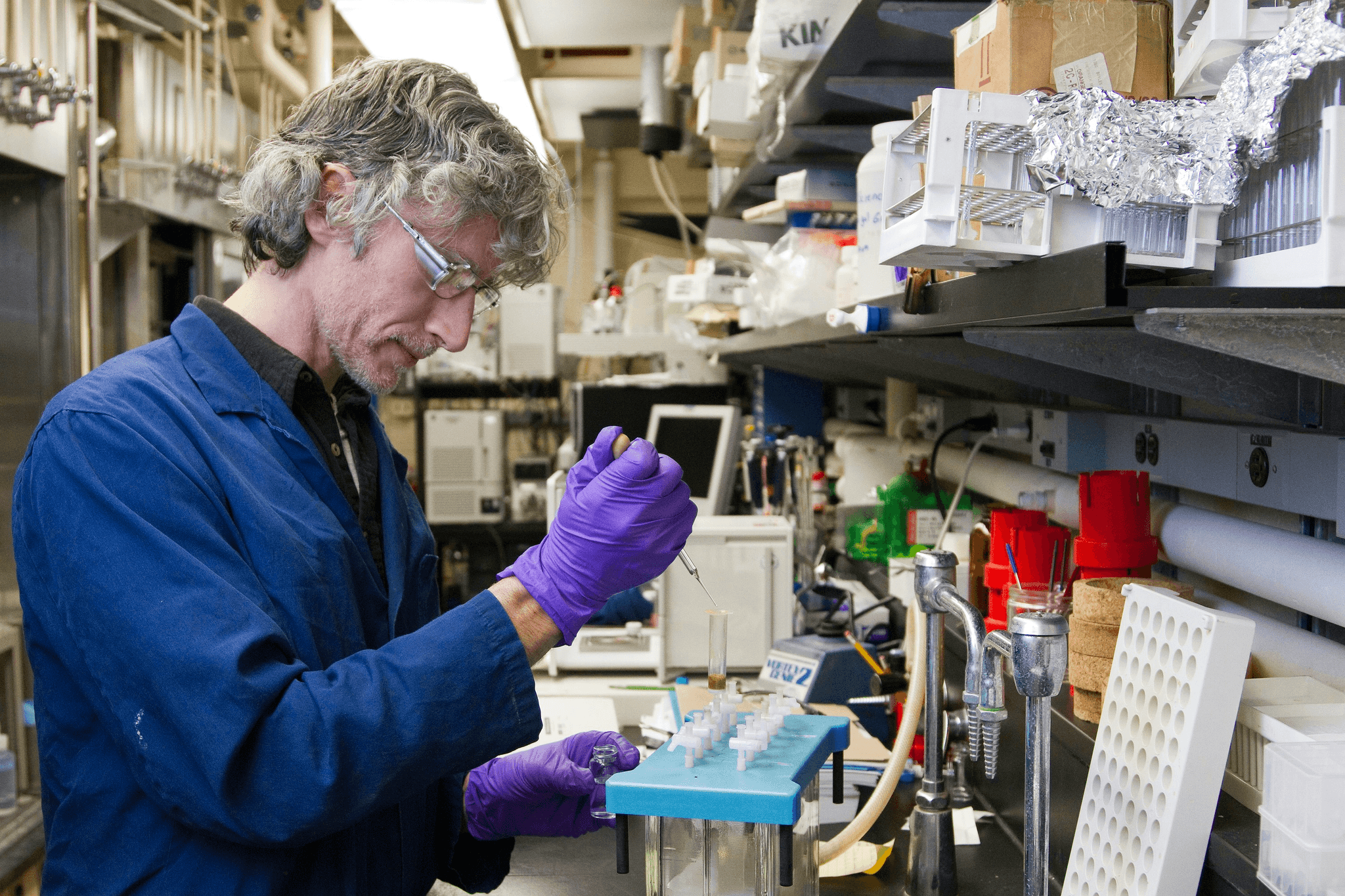

Laboratory Tests for Conductivity

Laboratory tests for conductivity typically involve using a device called a four-point probe, which measures the resistance of the stainless steel sample and calculates its conductivity. This method provides precise and accurate results, making it ideal for applications where exact measurements are required. Additionally, these tests can also help identify any impurities or defects in the metal that may affect its conductivity.

Field Tests for Conductivity

In addition to laboratory tests, field tests can also be conducted to assess the electrical conductivity of stainless steel in real-world conditions. These tests may involve using portable conductivity meters or other handheld devices to quickly measure the metal's electrical properties on-site. While not as precise as laboratory tests, field tests provide valuable insights into how stainless steel performs in practical applications.

Interpretation of Conductivity Test Results

Once the conductivity tests are complete, it's essential to interpret the results accurately to understand how well stainless steel conducts electricity. The test results will provide valuable information about the metal's electrical properties and how they may impact its performance in various applications. By carefully analyzing and interpreting these results, engineers and designers can make informed decisions about using stainless steel in electrical applications.

Conclusion

Stainless steel is a versatile and reliable material with excellent electrical conductivity. Understanding stainless steel conductivity is essential for anyone working with electrical applications. By knowing its properties and limitations, you can make informed decisions about using it in your projects.

Understanding Stainless Steel Conductivity

Stainless steel conductivity is due to the presence of chromium and nickel, which allow for the flow of electrons. This makes it an excellent choice for various electrical applications, from household appliances to industrial equipment. However, it's important to note that different grades of stainless steel may have varying levels of conductivity, so it's crucial to select the right type for your specific needs.

Practical Applications of Stainless Steel in Electrical Conductivity

Stainless steel's conductivity makes it an ideal material for electrical enclosures, wiring, and connectors. Its resistance to corrosion and high temperatures also make it suitable for use in harsh environments where other metals may fail. Additionally, its aesthetic appeal and durability make it a popular choice for consumer electronics and household appliances.

Considerations for Using Stainless Steel in Electrical Applications

When using stainless steel in electrical applications, it's important to consider factors such as alloy composition, surface finish, and temperature conditions. These can all impact the material's conductivity and overall performance. Proper testing should be conducted to ensure that the stainless steel used meets the specific requirements of the project.

In conclusion, stainless steel does conduct electricity effectively and has a wide range of practical applications in various industries. By understanding its properties and considering key factors when using it in electrical applications, you can take full advantage of its benefits while mitigating potential challenges.